Pittsburgh Corning Europe

small.JPG)

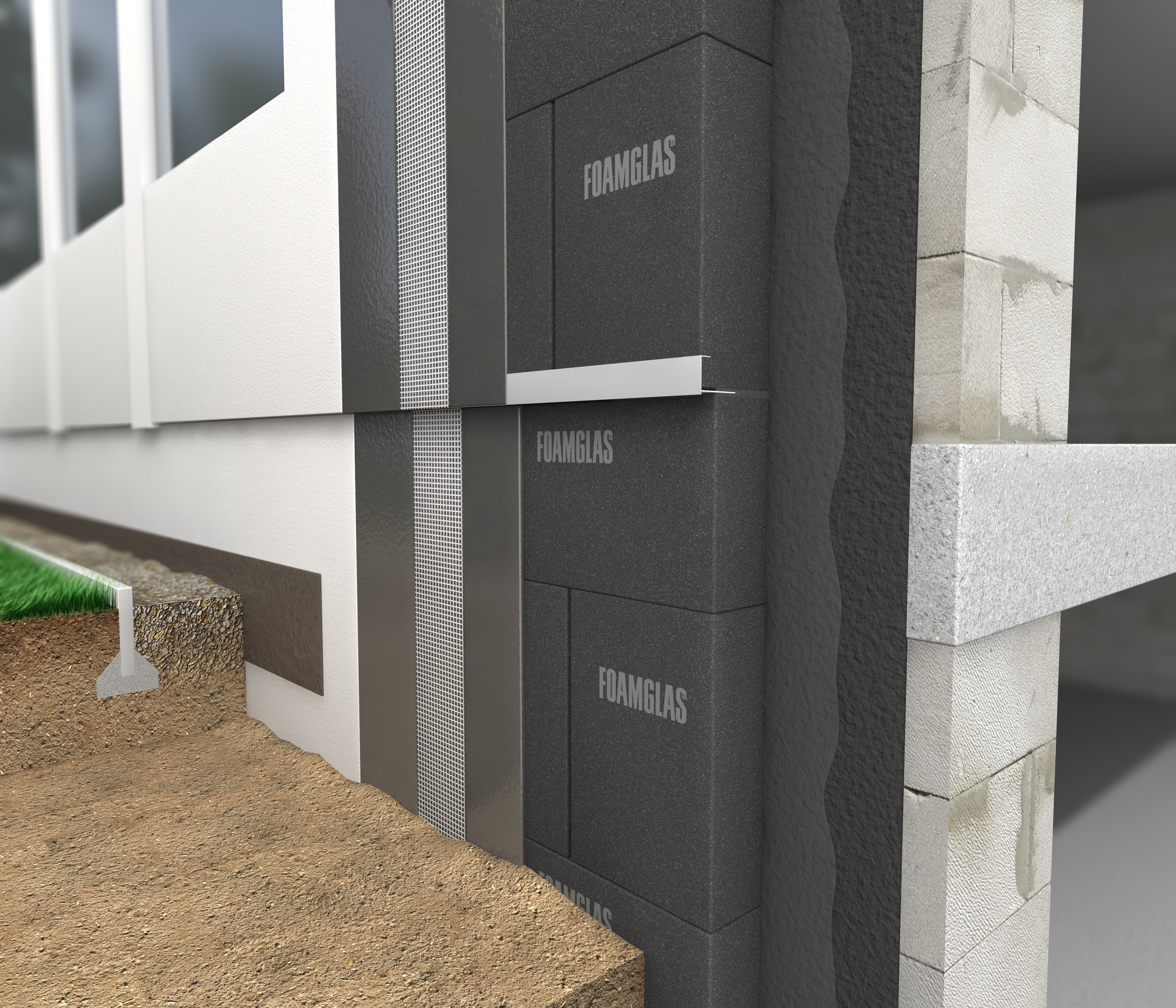

PCE & PCC are an international European & US-group of manufacturers and sales organisations of cellular glass thermal insulation, world-wide known under the name FOAMGLAS®.

PCE & PCC are an international European & US-group of manufacturers and sales organisations of cellular glass thermal insulation, world-wide known under the name FOAMGLAS®.

FOAMGLAS® cellular glass thermal insulation combines and ensures high performance, durable & ecologically sustainable thermal insulating in building & industrial applications.

Cellular glass offers outstanding system advantages that achieve a very favourable cost-benefit ratio over the service life of a building and industrial installations. Due to its hermetically sealed cell structure, cellular glass is extremely in-compressible, absolutely waterproof and sealed against vapour diffusion, and does not absorb any moisture. FOAMGLAS® is the only insulating material in which the vapour barrier, due to its material structure, is already “built in”.

Excellent Ecological profile

FOAMGLAS® insulation systems are stable under all conditions of use and protects the owner from unexpected expenditures for heating or expensive replacement of the insulation or repair. FOAMGLAS® systems safeguard the

environment one way or another. They allow for energy saving and, from the cradle to the grave, they do not contribute to environmental pollution, a safe product consistent with the principles of building physics. Cellular glass is certified to standards of health and indoor air quality. Ecologically viable product recycling is possible in the case of building demolition.

Environmentally friendly production

The raw materials used in the FOAMGLAS® production are inherently mineral and thus environmentally friendly. Principal raw material is recycled glass. Further raw materials are feldspar, sodium carbonate, iron oxide, manganese oxide, carbon, sodium sulfate and sodium nitrate. By the introduction of recycled glass into the production FOAMGLAS® makes a relevant contribution to the protection of the environment.

Minimal environmental pollution

Due to improvements in process engineering and in the energy supply (coming from hydro power electric energy) significant progresses has been achieved in recent years regarding air pollution, greenhouse gas emissions, consumption of energy and resources.

Reduction of the production energy means that the time period for energy amortization of the investment in thermal insulation – as an important evaluation unit – is considerably reduced.

World resources

The principal raw material of FOAMGLAS® production today is selected recycled glass (in the past the main raw material was silica sand). The supplies of recycled glass are ample, as in the construction and other industries large quantities amass and have to be disposed of as waste. Plastic foam insulation, however, is produced from crude oil, which is a non renewable fossil fuel.

Service life

Service life

Having outstanding qualities (mineral, impermeable to water and vapor, resistant to acids, non-combustible, hightemperature resistant), cellular glass is a very durable material. The long service life of the material has very positive effects, ecologically and financially, on the service-life of the construction and, consequently, on the life of the building. Maintenance and replacement cycles can significantly be reduced by the use of durable materials.

Emissions / nuisance during installation and use

Cellular glass does not release harmful or toxic components into the environment. It does not contain green house gases or ozone depleting products, no flame retardant and no con-taminative or carcinogenic particles and fibers.

When recommended installation instructions are followed, cellular glass insulation does not produce emissions that degrade the environment or health, at production, installation nor use.

Emissions in case of fire

Dumping and burning of construction waste is most critical for the environment, even in small quantities. In particular plastic foam materials are classified as harmful. In the case of burning of these materials high levels dangerous emissions are released than in combustion in an incineration plant. Studies have been conducted in Germany on thermal combustion of polystyrene insulation, which clearly indicated that released fumes are acutely toxic. Serious adverse health effects in the long-term cannot be excluded. Even with combustion in a waste incineration plant, there is high impact to the environment, as annually several thousand tons of slag and filter residue have to be transported to special disposal sites. The non-combustibility of cellular glass makes the toxicity issues irrelevant.

Waste disposal

In the assessment of insulation materials one consideration is repercussions on the environment from waste disposal. There are significant differences between the various insulation products. In total evaluation – and considering the scarcity of raw materials – as documented in eco-balance data sheets for the building industry, plastic foam insulation receives poor ratings for environmental pollution.

Recycling

Cellular glass being non-combustible, combustion in a waste incineration plant is not a possibility. An option is the recycling of cellular glass as crushed stone (for bedding in road construction) or infill material for noise barriers.

Recycled FOAMGLAS® is a safe and suitable product for these applications, as it is dimensionally stable, neutral for the environment, inorganic, rot-proof and without any risks for the ground water (meets ELUAT-test requirements).

If crushed and recycled FOAMGLAS® is not used as bedding or infill material, it can be taken to an inert waste disposal site, like crushed concrete or brick.

FOAMGLAS® – a valuable contribution to the protection of the environment.

Today FOAMGLAS® is made from 60 %+ recycled glass. The FOAMGLAS® manufacturing concept is waste reduction and green energy utilisation.

For the FOAMGLAS® production only energy from renewable sources is used.

FOAMGLAS® insulation meets all environmental and health requirements for construction products.

At the end of its service-life FOAMGLAS® disposal is simple. One option is the use of recycled cellular glass as infill in trenches or back-up for buried pipes.

FOAMGLAS® has an outstanding service-life, which is clearly the best for the environment.

On balance: FOAMGLAS® is an insulation concept fit for the future that gives an answer to the genuine concerns for the environment. The system ensures that all demands on performance, durability, environmental integrity and sustainability are fulfilled.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec laoreet ipsum id augue varius, sed fringilla lacus congue.

No news articles.

No news articles.